What is ABS?

One of the well-known and significant filaments in the 3D printing industry is ABS, or Acrylonitrile Butadiene Styrene, which is highly popular due to its great compatibility. This filament is a thermoplastic that can be shaped at high temperatures, offering high durability while maintaining maximum quality and exceptional flexibility. As a result, it has become one of the most widely used filaments in most industries, allowing the creation of various shapes.

History of ABS

ABS polymer has applications beyond 3D printers. This material has been available in various forms since the 1940s but became a globally used material in the 1950s. Additionally, due to its diverse polymer compositions, it is a practical material in polymer engineering. This polymer is used in piping systems, boats, automotive parts, medical devices, commercial panels, and even the food industry. Nowadays, this material can be found almost everywhere and is abundant.

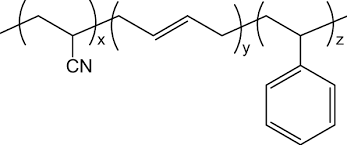

If we look at the chemical composition of ABS, we notice it has a petroleum base and high strength. Importantly, by adding additives, a wide range of ABS plastic materials can be produced.

Today, ABS polymers are considered valuable for industries because they are easy to process and machine. In its raw form, this material has a slight yellowish tint and is used as small, rounded granules in various industries

Why ABS?

The most important advantage of ABS is its affordable and reasonable price.

Given its flexibility, high quality, and ability to print details, along with being available in various colors, it allows for the creation of attractive shapes. Additionally, dimensions are precisely maintained during the printing process.

It’s worth noting that the strength of filaments lies in their resistance to heat and their ability to withstand impacts, making ABS suitable for large-scale industries as well. Overall, ABS filament significantly increases printing speed, which reduces the final cost of products. Printing with this filament is very easy, and it can be polished and machined. ABS filament is suitable for printing objects subject to wear or pressure. For example, when pressed, it bends and deforms before breaking, whereas PLA filament breaks quickly.

Unlike PLA, ABS is not biodegradable since it is a petroleum-derived material, but it is common to send print waste to plastic recycling companies.

If you’re an expert in filaments, you likely know that temperature is a critical and highly influential factor in the shapes produced by a 3D printer. A notable point about ABS filament is its strength and durability at very low temperatures, remaining robust and resistant even in the coldest environmental conditions, making it usable in all weather conditions.

Key Tips for Using ABS Filament

To achieve optimal results with ABS filament, follow these essential tips:

Stable Environment: Place your printer in a location with consistent temperature. Temperature fluctuations can affect print quality. Ensure the cooling fan is off or set to low speed to prevent surface irregularities.

Low Print Speed: Slower printing speeds allow each layer to cool properly before the next layer is applied, reducing the risk of corners lifting or detaching for better results.

Moisture Control: ABS filament naturally absorbs moisture, so store it properly to maintain its quality.

Applications of ABS Filament in Various Industries

ABS thermoplastic, known for its unique properties, is widely used in industries such as plumbing components, automotive parts, prototyping, toy manufacturing, and more.